Managing the Doldrums of Winter

There are things pilots can do to keep themselves and their aircraft prepared during extended periods of gray.

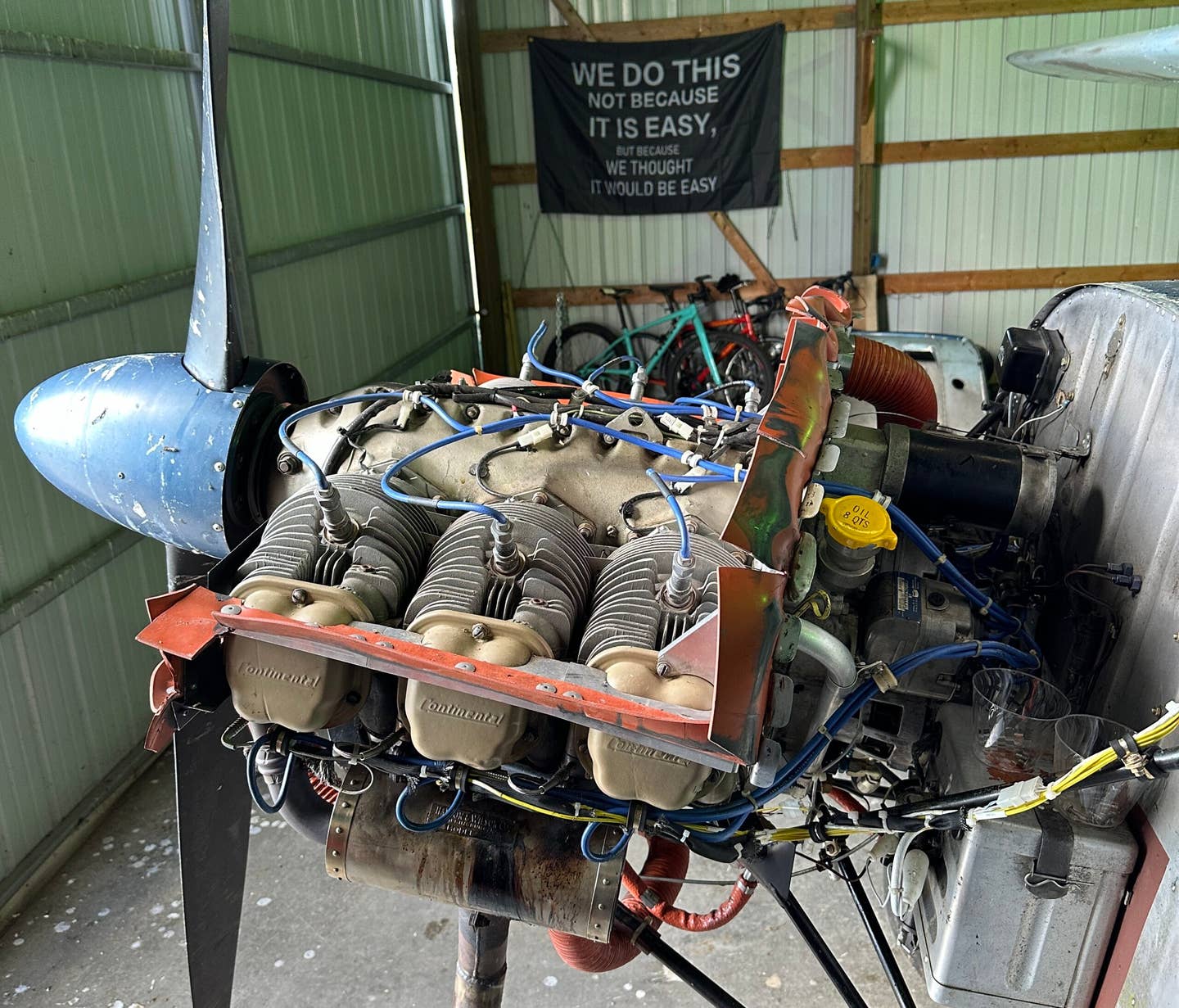

Every aircraft owner in a cold and snowy climate must anticipate the multitude of nonflyable days this time of year. [Courtesy: Jason McDowell]

There comes a time in every Wisconsin winter when an extended period of gray renders you not only unable to remember where you put your sunglasses but also to recall when you last needed them at all. Warm, golden sunlight becomes a distant memory and a magical aspiration, viewable only through the window of one’s cellphone while browsing social media feeds. It’s a dismal, dreary time. But on a positive note, the mosquitoes aren’t so bad.

This winter, we received about a foot of snow in one shot, followed by a week of subzero temperatures and high winds. That was about a week and a half of nonflyable weather for those of us still building our tailwheel skills. When the winds finally subsided they were replaced with temperatures in the upper 30s…which resulted in 200-foot ceilings and thick fog. We’re going on week two of these conditions, and it’s now been a full month since I’ve been able to fly at all.

Every aircraft owner in this climate must anticipate conditions and nonflying periods like this. But this is doubly important for relatively new owners like me still learning how to best care for their airplanes and refining flying skills. Gone are the days of landing the FBO’s rental airplane, tossing the keys to the person at the front desk, and forgetting about it for a few weeks. Now, as the caretaker of an airframe and engine, there are more responsibilities to consider.

So, as someone new to ownership, what should you consider when facing weeks upon weeks of nonflyable weather? For me, there are two primary areas of focus—the engine’s health and my perishable flying skills.

It’s fairly common knowledge that the worst thing you can do to an airplane engine is let it sit unused for long periods. This makes every potential window of flyable weather that much more valuable, considering it might be followed by a month of inactivity. This is why, on my last flight, I pushed my limits a bit and ventured out on an extremely slick runway covered in mud and snow.

That flight amounted to only one trip around the pattern. But with a thoroughly preheated and then warmed-up engine, the engine did, in fact, reach normal operating temperature as I was turning downwind. The ensuing sketchy runway conditions were bad enough to make me call it a day, but having gotten my engine up to temp, I effectively reset its “sitting on the ground” meter, and I felt better about having to leave it parked for the following weeks.

To ease the strain of starting an engine in frigid temperatures, I do a few things. First, I invested in the best engine preheating system money could buy, utilizing my rule that if the cost to upgrade from the cheapest to the best product available is three figures or less, I just do it. Like most systems, my Reiff preheater has a heating element on the oil pan…but it also has a metal band mounted around each cylinder to heat the entire engine evenly. This also prevents the introduction of piping-hot oil into ice-cold cylinders during start-up.

Similarly, I make a point of storing quarts of oil at home in a warm kitchen cabinet. This way, you’re adding nice warm oil into the engine if you need to add a quart. If your significant other complains about 20W-50 next to the corn flakes, simply put the situation into perspective by pointing out how you could be building an entire experimental aircraft at home but choose instead to hangar a prebuilt example at the airport for their convenience.

On the evening before each winter flight, I’ll drive out to the airport to plug in the preheater. Yes, there are devices to remotely activate such systems via a cellphone or Wi-Fi signal, but I take the opportunity to inspect both the airplane and runway. More than once, I’ve discovered an abysmal snow plowing job, mechanical issue, or some other problem that would have resulted in a canceled flight the following morning.

With a properly cared for and warmed-up engine, my next concern is my proficiency, particularly as a relatively new tailwheel pilot. Just as it’s bad to let your engine sit unused for extended periods, the same goes for your skills. With a typical Monday through Friday 9-to-5 schedule, the lack of daylight in the northern states this time of year effectively limits flying to only Saturday and Sunday. From there, low ceilings or high winds only have to occur a few times to thoroughly ruin a month of flying.

It’s a balancing act. On one hand, you want to respect your personal limits when you’re beginning to get rusty. On the other hand, pushing your limits a bit on a less-than-perfect day might give you the mental reset you need to sharpen your skills and regain some confidence. This will better prepare you to get through the next long period of poor weather and no flying.

It’s always good to go up with an instructor from time to time. If faced with a marginal day with, for example, winds outside of your personal limits, it might be a great opportunity to go up for a lesson, giving you the mental and mechanical reboot necessary to get through another few weeks on the ground.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox